The 3nh TS7600 Series Intelligent Colorimeter adopts dual-optical-path compensation technology, ensuring measurement accuracy is stably maintained at ΔE*ab ≤ 0.01. It precisely resolves color deviation issues in paint films, empowering enterprises to enhance product quality and boost market competitiveness.

Why need colorimeter in paint and coating industry

In the quality control of the paint and coating industry, color difference detection is a critical process that directly impacts product appearance quality and market competitiveness. Threenh Technology’s colorimeters have become the industry’s preferred choice thanks to their outstanding performance. Color testing of paint films presents numerous challenges, such as variations in surface gloss and batch stability control, all of which Threenh Technology has excellently addressed through technological innovation.

The Threenh technology‘s Intelligent Colorimeter adopts advanced dual-optical-path compensation technology: the main optical path captures sample signals, while the auxiliary optical path real-time monitors light source fluctuations and performs dynamic compensation. This ensures that measurement accuracy remains stably at ΔE*ab ≤ 0.01 even during long hours of continuous operation. Equipped with a D/8 (diffuse illumination, 8° viewing angle) measurement geometry and paired with the SCI (Specular Component Included) measurement mode, the device accurately captures the true color of paint films, eliminating measurement deviations caused by differences in surface gloss.

In terms of parameter support, the Threenh Paint Colorimeter covers over 20 professional color parameters including Lab, Lch, ΔEab, ΔEcmc, and ΔE*94, meeting testing requirements across diverse industry standards. Built-in with a variety of standard light sources (D65, A, F2, F7, F11, etc.), it simulates color performance under different lighting conditions, enabling enterprises to pre-assess product color effects in real-world application scenarios. With a fast measurement speed of 1 second per test and over 9,000 consecutive measurements on a single charge, it can almost fully satisfy the high-frequency testing demands of paint production lines.

For full-process management of paint production, 3nh Technology provides a comprehensive supporting solution. Its dedicated color quality control software and color matching software comes with a vast built-in database of paint color codes, automatically calculating color mixing formulas based on measurement data. This helps technicians quickly formulate colors that meet standards, significantly shortening the color mixing cycle. The device also supports connection to online production line testing systems, real-time monitoring color changes during paint production, and feeding data back to the color mixing system for parameter adjustments, thus achieving closed-loop quality control.

What brand is recommended for paint color measurement

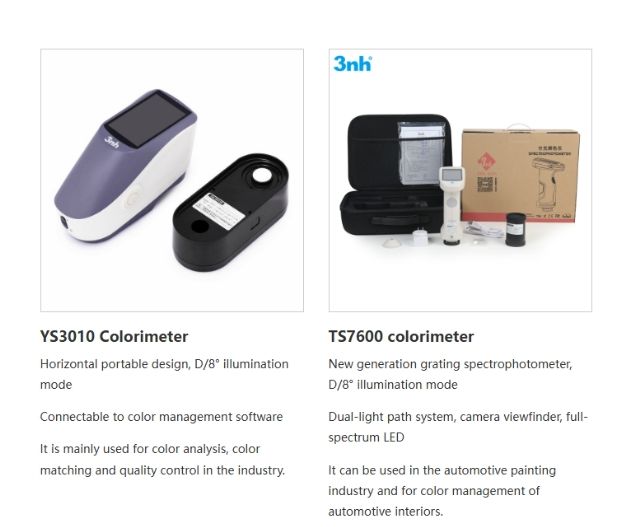

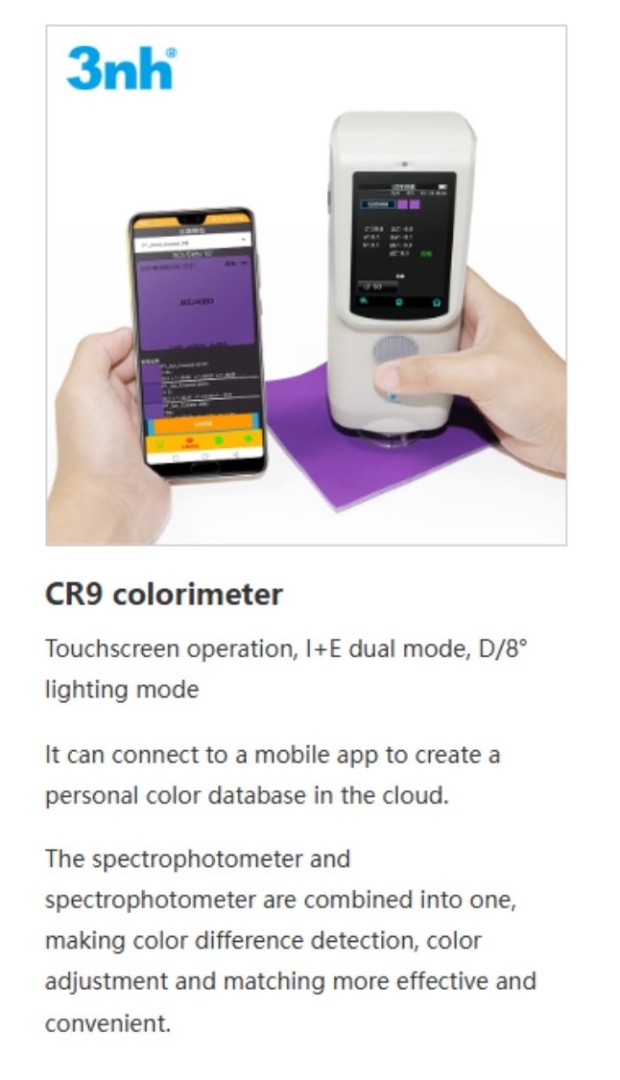

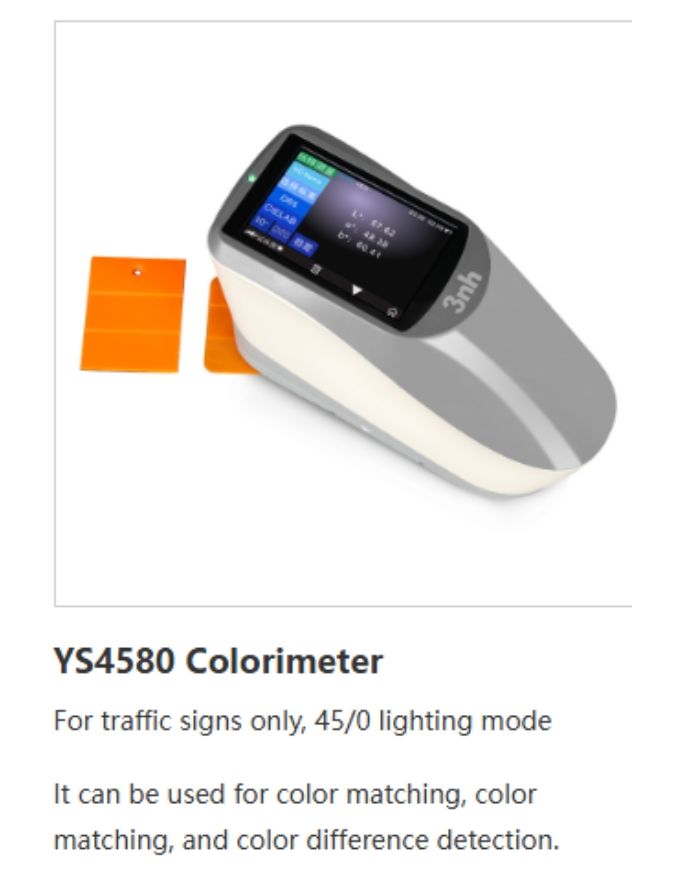

Coating Colorimeters (Also Known as Paint Color Difference Testers), Coating colorimeters are widely used across sectors including paint and coatings, powder coatings, ink coatings, automotive paints, decorative coatings, spray painting & powder spraying, and architectural coatings. If you are looking to select a coating colorimeter, this article will provide insights into product specifications, application fields, color management in the coating industry, as well as a range of coating colorimeter models. The 3nh colorimeter series comprises six products, including portable spectrophotometers YS3010/YS4580 and handheld colorimeters NR110/NR60CP/TS7600/CR9.

Paint & Coating Colorimeters

The NR110 and NR60CP are categorized as paint and coating colorimeters. Compact and handheld, they are ideal for use on production lines in industrial manufacturing facilities. Both models adopt the D/8° illumination geometry.

The NR110 offers expanded functionality via PC connection and is equipped with dual apertures (flat and sharp).

The NR60CP is suitable for measuring small concave surfaces and large flat areas, featuring 4mm sharp-tip and 8mm flat-platform dual apertures, with a color difference accuracy of ΔE*ab ≤ 0.03. It comes with light/cross positioning and is a cost-effective all-round handheld device.Both instruments support standalone operation without the need for a computer connection.

Spray Coating spectrophotometer

The YS3010 and TS7600 are spray coating colorimeters and grating spectrophotometers, both utilizing the D/8° illumination geometry. The YS3010 employs horizontal grating spectroscopy, while the TS7600 adopts planar grating spectroscopy.

The YS3010 is designed for color difference analysis and quality control, ideal for measuring objects larger than 8mm. It is fitted with camera positioning and an 8mm measurement aperture, boasting an accuracy of ΔE*ab ≤ 0.05.

The TS7600 series grating spectrophotometer incorporates 4th-generation advanced technology and dual-path sensors.These two models are suitable for laboratory color measurement, color formulation, and precise color communication.

TS7600 Core function: Enables accurate measurement of fluorescent paint colors, using pulsed xenon lamps with a wider spectral range to adapt to various scenario requirements.

Powder Coating Colorimeters

The CR9 is a portable, universal powder coating colorimeter and a highly cost-effective spectrophotometer. It adopts the D/8° illumination geometry and integrates the functions of a spectrophotometer and a color matching tool in one device, enabling convenient and efficient color difference detection and color formulation. By connecting to a mobile app, users can measure colors, search through a color card database, automatically match trending colors, and store a vast volume of color data within the app.

Core function: After the powder coating is placed into a cuvette or powder test box, it can be accurately measured by a spectrophotometer.

Color Management for Powder Coatings

Bench-top spectrophotometers for coatings can accurately measure the reflection spectrum of powder coatings across all wavelengths, yielding precise color values. To measure powder coating samples, simply place the powder into a cuvette or powder test cell, then follow the instrument’s operating instructions for measurement. This data management capability helps enterprises establish standardized color databases, providing robust support for product R&D, production, and sales.

Large-Aperture Architectural Coating Spectrophotometer

The YS4580 is an architectural coating colorimeter specifically designed for traffic road signs. It is configured with a 20mm aperture and 45/0° illumination geometry (45° annular illumination, 0° viewing angle), and supports customizable color tolerance with an accuracy of ΔE*ab ≤ 0.04. It is used to measure the luminance factor and chromaticity coordinates of traffic signs, road markings, and reflective films, preloaded with standard color data compliant with GB 2893 and GB/T 18833, and allows manual customization of polygonal rectangular color tolerance. The YS4580 is suitable for precise laboratory color analysis and communication, and can also be used for measuring fluorescent samples.

Core function: Eliminates the specular light of textured surfaces and accurately measures color data that closely matches visual perception.

Introduction to Professional Color Mixing Software for Paints and Emulsion Wall Paints

Industries such as paint, printing, and textiles typically require mixing colorants in specific proportions to achieve the target product color. Manual trial-and-error mixing is an extremely cumbersome, labor-intensive, and time-consuming process. Today, we introduce a professional computer-based color mixing software designed for industrial production, helping you generate color matching schemes quickly and accurately.

3nh Color Mixing System – Pecolor: Professional Color Matching Software

Independently developed by 3nh, this professional color mixing software is designed for use with spectrophotometers. It features easy operation, precise color matching, automatic color correction, and high cost-effectiveness.

Users can obtain accurate color matching solutions by following these steps: establishing a basic colorant database → measuring samples → automatic color mixing via color dispensers → creating color swatches → measuring color swatches → calculating color differences → revising formulas. All formula data is managed digitally, which saves color mixing time, improves mixing efficiency, enhances product color matching quality while reducing costs, and frees up more capital and personnel resources for developing new color matching schemes.

Paint Color Mixing Steps

Enter Basic Colorant Data

Create a new colorant group

Input colorant gradient data

Complete colorant entry

Enter Target Color (Measure the target color with a spectrophotometer or directly input color data)

Calculate Formulas

Select the colorants to be used

Set color matching parameters

Generate formulas via calculation

These are all the operational steps for using 3nh’s Pecolor color mixing software. Isn’t it simpler and more user-friendly than manual color mixing? What’s more, our after-sales team provides dedicated operational training delivered by professional technical engineers!

2025 PeColor Paint Edition: Four Core Upgrades

Addressing key industry pain points, PeColor launches its 2025 Cloud-Based Color Mixing Software (Paint Edition), which reconstructs the color mixing workflow around the concept of "Intelligence + Collaboration".

Multi-Device Account Sync: Breaking Down Data Silos

Cloud Formula Library: Supports team-wide multi-account formula sharing, with real-time synchronization of Lab values, pigment ratios, and historical data.

Cross-Device Collaboration: Seamless data integration across laboratories, workshops, and client terminals, eliminating errors in information transmission.Cloud Color Mixing System | Multi-Device Collaborative Color Matching Software

Upgraded AI-Powered Color Matching Algorithm

Precise Formula Prediction: Integrating with spectrophotometer data, the AI algorithm generates 3 optimal formulas in 1 second, with color difference controlled at ΔE ≤ 0.5.

Dynamic Correction Function: Automatically adapts to raw material variations across batches, reducing manual correction time by 80%.AI-Intelligent Color Matching Software | Spectrophotometer Integrated System

Full-Process Cost Control

Inventory Pigment Matching: Prioritizes using in-stock raw materials for formula generation to minimize procurement waste.

Cost Simulation Calculation: Displays real-time cost per color mixing batch, with support for cost comparison and optimization recommendations.Cost-Saving Color Mixing Tool | Pigment Utilization Optimization Software

In-Depth Adaptation to Industry Scenarios

Exclusive modes for diverse sectors including coatings (architectural/automotive paints), inks (printing/packaging), and textile dyeing & printing.

Provides quick-start tutorials for beginners and customized enterprise training services.

One-Stop Color Management Solutions

In addition to providing powder coating colorimeters, 3nh Technology offers clients comprehensive one-stop color management services. Covering the entire spectrum from color standard establishment, color data collection, and color quality evaluation to color problem resolution, 3nh helps enterprises develop and implement color management systems, ensuring color consistency and stability throughout production. Color management is the lifeline of the coating industry. With their outstanding performance and holistic solutions, 3nh coating and powder colorimeters deliver powerful support for color management in the coating sector. We firmly believe that with ongoing technological advancements and market growth, 3nh Technology will continue to drive innovation in color management for the coating industry, creating greater value for enterprises worldwide.

Media Contact

Company Name: Threenh Technology

Email: Send Email

City: Beijing

Country: China

Website: https://www.threenh.com/