Basics

– Electrolytic capacitor definition

An electrolytic capacitor is a type of capacitor that uses an electrolyte to produce a higher capacitance than other types of capacitors. The electrolyte is a fluid or gel with a large number of ions. Most electrolytic capacitors have polarization, which means that the voltage at the positive electrode must be greater than the voltage at the negative electrode. The high capacitance of electrolytic capacitors has advantages and disadvantages. They are characterized by high leakage current, equivalent series resistance, and limited service life. Electrolytic capacitors can be wet electrolytes or unidirectional polymers. They are usually made of aluminum or tantalum, but other materials can also be used. The supercapacitor is a unique electrolytic capacitor, usually called a double-layer capacitor. Their power range can range from hundreds of farads to thousands of farads. This article is based on aluminum electrolytic capacitors. Their typical capacitance ranges from 1mF to 47mF, and their operating voltage ranges from a few volts to hundreds of volts DC. Aluminum electrolytic capacitors can be used in a variety of applications, including computer motherboards, power supplies, and various household appliances. Since they are polarized, they can only be used to power DC circuits.

– How Electrolytic Capacitors are Made

The figure above is the internal structure diagram of a commonly used electrolytic capacitor. Most electrolytic capacitors (also known as e-caps) are polarized capacitors that are mainly formed of two thin layers of metal foil and paper spacer filled with electrolyte. A dielectric oxide layer acts as a dielectric medium – electrical insulation amid anode and cathode foil.

– Electrolytic Capacitors Symbol

There are two symbols for capacitors typically employed to represent capacitors in the field of electronics. One symbol is used for capacitors that are polarized, and another symbol is used for capacitors that are not polarized.

In the diagram above the symbol with one curved plate is a Polarized Capacitor. The curved portion represents a cathode (negative) of the capacitor, while the opposite plate represents one of the electrodes (positive). Sometimes a plus sign is also added to the positive side. The most common symbol for an electrolytic capacitor (polarized capacitor). The left diagram is by IEC standard (Europe) while the right one is by ANSI standard (the US).

– Why Choose Electrolytic Capacitors

An electrolytic capacitor can adapt to higher frequency circuits than a usual ceramic capacitor can do because of its high capacitance values. Besides, they do a better job than super-capacitors in handling ripple current. And they are built to low volume which saves lots of space on a board, saving direct cost.

Types & Applications

The electrolytic capacitor is a big family and has developed for nearly a century as a classic passive electronic component. Among the wide spectrum of e-cap, there are 3 kinds of them widely used in industry practice. They vary from each other in size, capacitance, and applications.

Aluminum, Tantalum and Niobium Electrolytic Capacitor

– Aluminum Electrolytic Capacitor

This kind of electrolytic capacitor has passed the longest period of design and manufacture, from the “Wet” type to the “Dry” type. They are named from the aluminum can which rolls up the anode and cathode and can be divided into the solid type and the non-solid type.

Nowadays, aluminum capacitors are largely used in camera flashes, automotive airbags, power-factor correction, etc.

– Tantalum Electrolytic Capacitor

Tantalum capacitors are much more long-price than aluminum electrolytic capacitors. They produce low leakage with a high capacity and are often used with ceramic or film capacitors in power supply decoupling targets. Tantalum electrolytic capacitors feature a self-healing mechanism that functions to reduce MnO2 electrolytes into insulating Mn2O3. In addition, they behave superiorly stable in harsh environments (especially high-temperature ambient).

– Niobium Electrolytic Capacitor

The niobium capacitor is relatively a young competitor in the market for the tantalum capacitor. They have a thicker dielectric layer and a lower breakdown voltage than tantalum capacitors. Besides the self-healing mechanism as tantalum capacitors inherent, niobium capacitors have one more feature: self-arresting mechanism. The mechanism operates to protect the chip from short circuits fault on account of local breakdown. What’s more, they excel in resisting vibrations and shocks.

Niobium electrolytic capacitors favor their use in consumer, industrial, automotive, aircraft fields, and so on.

Cautions

– Do not Reverse Bias an Electrolytic Capacitor

An Exploding Capacitor

Although some bipolar e-caps can withstand a certain reverse voltage for a while, the constructing characteristics determine that electrolytic capacitors should be run from a higher voltage on the positive end and a lower one on the negative end.

Furthermore, general polarized electrolytic capacitors are designated to work only in a DC circuit, not AC circuits. Errors or damages may take place if the reverse voltage is connected to an e-cap.

• Explosions due to short circuits between two terminals

• Blast from the pressure generated by H2 in the oxide layer

• Overheat resulting from smaller resistivity and damage the overall capacitor

– Electrolytic Capacitor may Wear Out

• How long do electrolytic capacitors last?

In general, their chemical reaction rate (life consumption) increases as temperature increases. The changing pattern is known as the 10-degree-rule. That is, every 10% of uplift by temperature brings about double the length of an electrolytic capacitor.

Besides, due to their structure, electrolytic capacitors are very subject to degradation in regards to long-term storage to PCB. Electrolyte evaporation and dielectric dissolution are two main degradation modes of electrolytic capacitors.

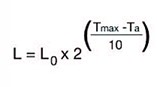

Electrolytic capacitors’ lifespan calculation can be demonstrated through the Arrhenius equation (figure 4) when designing circuits. Although it should be noted that the life calculation formulas vary from manufacturer to manufacture, they are all similar.

L: Estimated life (Hr)

L0: Life at rated temperature (Hr)

Tmax: Rated Temperature (°C)

Ta: Ambient Temperature (°C)

You can refer to the datasheets of specific capacitor products for those parameters listed above.

• Constant Test is Needed

A simple way to go is to check and replace the electrolytic capacitors every several years to prevent them from hindering the operation of the circuits or causing further damage.

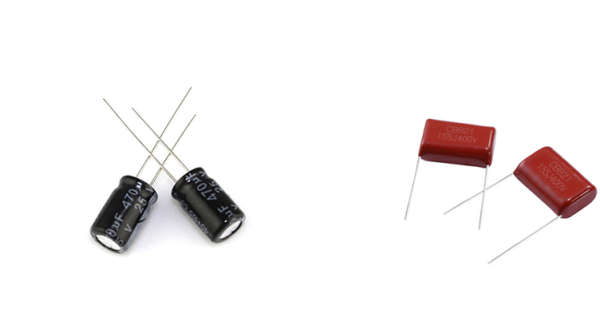

Difference between Film & Electrolytic Capacitors

As the two most frequently implemented capacitors, film capacitors and electrolytic capacitors differ from each other in many ways.

– Structure & Performance

Electrolytic capacitors utilize a dielectric material that cannot offer perfect insulation to separate the conductive plates, resulting in large ESL (Equivalent Series Inductance) and ESR (Equivalent Series Resistance) leakage. Thus, the heat dissipation of electrolytic capacitors is more serious than the non-inductive winding film capacitors when experiencing a large ripple current.

– Capacitance Tolerance

As for this capacitance tolerance, electrolytic capacitors are generally valued at about 20% while film capacitors often rate 10% or 5%, which is the most common value of capacitors.

– Size

Usually, the size of film capacitors is larger than that of the electrolytic capacitor. And it is one of the main factors that contribute to the low impedance of electrolytic capacitors.

– Lead Length:

An electrolytic capacitor has two leads of uneven length within which the shorter one is negative and the longer one is positive. Film capacitors are non-polar so they have two leads of equal length.

– Capacity Value

The capacity value of the electrolytic capacitor can be made very large. The relative capacitance of the film capacitor is relatively small.

– Safety

The film capacitors are relatively safe and easy to use compared with electrolytic capacitors under the same storage conditions. The environment required by the electrolytic capacitor in the process of use is more stringent.

– Explosion-proof Groof

Because of the characteristics of electrolytic capacitors, they are usually engraved with grooves at the bottom of the body to prevent explosions from bringing secondary damage to other components on PCB boards.

The difference between ceramic capacitors and electrolytic capacitors

structure:

For ceramic capacitor ceramics, ceramic is used to separate the conductor from the surface.

For electrolytic capacitors, the metal oxide layer and electrolyte form a conductive surface.

Dielectric:

For ceramic capacitors, the ceramic substance forms the dielectric.

For electrolytic capacitors, the dielectric consists of a tiny oxide layer.

polarization:

Ceramic capacitors are not polarized.

Electrolytic capacitors are polarized.

ESR:

Ceramic capacitors generally have low ESR.

The ESR of electrolytic capacitors is often larger and depends more heavily on frequency.

microphone:

Since mechanical vibrations generate electrical signals in the circuit, ceramic capacitors will experience vibrato.

Electrolytic capacitors will not exhibit vibrato.

Final Thoughts

Several factors you need to think twice upon when choosing an electrolytic capacitor include appropriate voltage ratings, ESR, ripple current, heat dissipation, and surge.

Also, we are glad to hear your thinking about the topic. If it helps you, please share it with your friends.

Media Contact

Company Name: EASYBOM, INC.

Contact Person: Media Relations

Email: Send Email

Phone: 718 – 737 – 2822

Address:506 2ND AVE STE 1600

City: SEATTLE

State: WA, 98104 – 2379

Country: United States

Website: www.easybom.com