MONTREAL, May 14, 2024 (GLOBE NEWSWIRE) -- PyroGenesis Canada Inc. (http://pyrogenesis.com) (TSX: PYR) (OTCQX: PYRGF) (FRA: 8PY), a high-tech company (the “Company” or “PyroGenesis”) that designs, develops, manufactures and commercializes advanced plasma processes and sustainable solutions which are geared to reduce greenhouse gases (GHG) and address environmental pollutants, is pleased to announce its financial and operational results for the first quarter ended March 31st, 2024.

“Q1 continues to confirm our contention that we have successfully rebounded off the low revenue mark of Q1 2023 and that our cost controls and project optimization efforts are having the impact we expected,” said P. Peter Pascali, President and CEO of PyroGenesis. “We now have 4 straight quarters comfortably exceeding that three-year low point, with this recent quarter being 34% clear. As we stated in our last earnings call, we had anticipated the upward revenue momentum of the last few quarters to continue, and while we remain cautious, we are every encouraged that the overall trend continues to be positive and upward.”

“I am pleased with this quarter,” said Mr. Pascali. “We achieved some notable milestones, both in terms of (i) existing projects such as the fumed silica reactor project on behalf of our client HPQ Silicon, and (ii) with regard to new market entry, as evidenced by new contracts signed, and advance negotiations underway, with several clients in industries as diverse as green cement to steelmaking to aerospace manufacturing. The company’s flagship technologies are now being assessed, tested, or in use across a much wider array of major heavy industry categories, in more primary jurisdictions globally, than even we once thought possible. In so many ways, we are just getting started.”

Mr. Pascali added, “We have more work to do as we continue our optimization efforts, but this is a good start, and with our backlog of projects holding strong above $28 million, and our sales pipeline growing, we become better positioned with each passing quarter to succeed in our stated goal of becoming a leader in heavy industry decarbonization technology solutions.”

KEY Q1 2024 FINANCIAL HIGHLIGHTS

- Revenue of $3.5 million, up 34.5% year-over-year vs. Q1 2023

- Revenue was up 16.2% vs. Q4 2023

- 3rd best Q1 revenue in Company’s history

- Backlog of signed and/or awarded contracts of $28.1 million as at May 14, 2024

- Margin of 21.7%

- EPS loss of $0.02

SUBSEQUENT EVENTS

- Post quarter end, in April 2024, the company announced a letter of intent for large-scale plasma remelting furnaces, with Constellium, one of the world’s largest aluminum transformation and recycling companies. The project’s phases include feasibility studies and implementing a demonstrator plasma-heated furnace system in one of Constellium’s aluminum casthouses.

- Post quarter end, in April 2024, the Company announced the signing of a contract with one of the top 5 largest steelmakers globally, to assess the applicability of PyroGenesis’ electric plasma torches for use in the client’s manufacturing facilities as a primary heat source in the steelmaking process, specifically during the production of direct reduced iron in electric arc furnaces.

- Post quarter end, in April 2024, the Company announced the signing of a contract with one of the world’s largest manufacturers of products that serve the mining and defense industries, to assess the applicability and examine the use of PyroGenesis’ plasma in their cast furnaces.

- Post quarter end, in April 2024, the Company announced a contract with an aerospace entity in Spain for the sale of PyroGenesis’ titanium metal powder with a particle size range of 15-63µm, for use in additive manufacturing, with the contract representing the Company’s initial commercial metal powder order direct from a European client – a significant milestone under the Company’s new direct distribution strategy.

- Subsequent to March 31, 2024, the Company sold 3,779,700 shares of HPQ Silicon Inc. to P. Peter Pascali, the Company’s president and CEO, for proceeds of $661,448, representing a share price of $0.175.

- In May 2024, P. Peter Pascali provided a $1 million loan to the Company with a maximum term of twelve months. The loan bears interest at 10% provided that if the loan is repaid within 45 days of the loan date, no interest shall be owing.

Q1 PRODUCTION AND SALES HIGHLIGHTS

The information below represents highlights from the past quarter for each of the Company’s main business verticals.

Q1 2024 continued the positive revenue growth trend that began in Q2 2023, through deployment of material and components received, after-sales support of previously delivered projects, and an overall progression against the project backlog.

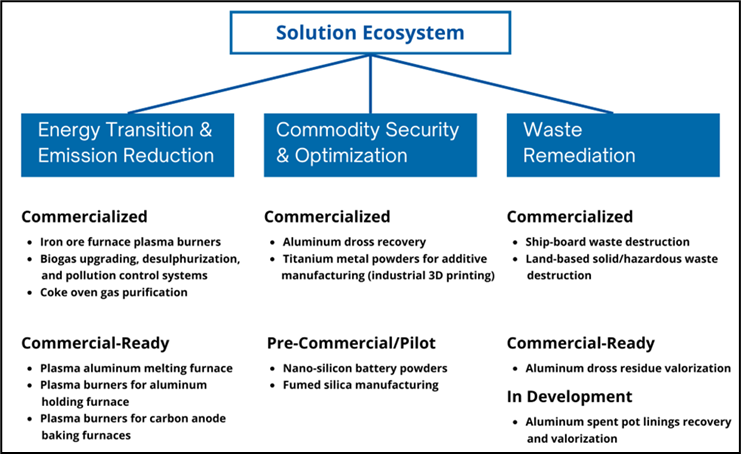

The Company operates within three verticals that align with economic drivers that are key to global heavy industry:

1. Energy Transition & Emission Reduction:

- fuel switching – utilizing the Company’s electric-powered plasma torches and biogas upgrading technology to help heavy industry reduce fossil fuel use and greenhouse gas emissions,

2. Commodity Security & Optimization:

- recovery of viable metals – and optimization of production methods/processes geared to increase output, maximize raw materials and improve availability of critical minerals,

3. Waste Remediation:

- safe destruction of hazardous materials – and the recovery and valorization of underlying substances such as chemicals and minerals.

Within each vertical the Company offers a selection of solutions at different stages of commercialization.

Energy Transition & Emission Reduction

- In January, the Company announced the receipt of a $667,000 non-refundable down payment under a master agreement for a potential multi-year plasma torch order with a US-based technology company, as part of negotiation related to a potential contract valued at over $10 million.

- In March, the Company announced a $450,000 contract for the sale of a plasma torch and furnace system for use in the development of “green” cement, to a U.S. structural materials entity engaged in the development of advanced cement materials. The project is funded in part by the U.S. Department of Energy.

Commodity Security & Optimization

- In January, the Company announced the results of a study showing improved economics for its fumed silica reactor (FSR) project, an initiative to convert quartz into fumed silica in a single step using a plasma reactor. The study results included potential EBITDA margins three times higher than the industry average of 20% and a capital investment 93% less than that required for building a conventional fumed silica plant.

- In February, the Company announced production milestones met for its FSR project, including the conclusion of engineering design and major fabrication, and the placement of orders for all additional periphery materials.

- In March, the Company announced accelerated construction of the pilot plant for its FSR project, having received all major equipment and components. The FSR pilot plant is being constructed within a dedicated space inside PyroGenesis’ facilities, with a 4,000 sq ft custom-designed infrastructure that meets the pilot plant’s unique ventilation, safety, and access requirements.

- In March, the Company announced the acquisition of intellectual property rights related to the PUREVAP™ nano-silicon reactor (NSiR) – on a no-cost bases – from HPQ Nano Silicon Powders Inc. (“HPQ Nano”), which had previously announced it would no longer be pursuing the commercial development of said technology in order to focus on other initiatives. Under the terms of a 2020 Development and Purchase Agreement between PyroGenesis and HPQ Nano, all rights in the PUREVAP NSiR process (including any intellectual property rights) were assigned to HPQ Nano on condition that should HPQ Nano choose not to commercialize the technology, PyroGenesis would have the option to have the ownership of this technology revert back to it at no additional cost. The PUREVAP™ NSiR is a proprietary process, originally designed and developed by PyroGenesis on behalf of HPQ Nano, a wholly-owned subsidiary of HPQ Silicon Inc., that can use different purities of silicon (Si) as feedstock to make a wide range of spherical silicon nano- and micro-powders and wires, for potential use across various applications including as a potential replacement metal in lithium-ion batteries.

FINANCIAL SUMMARY

Revenues

PyroGenesis recorded revenue of $3.5 million in the first quarter of 2024 (“Q1, 2024”), representing an increase of $0.9 million compared with $2.6 million recorded in the first quarter of 2023 (“Q1, 2023”).

Revenues recorded in the three-months ended March 31, 2024, were generated primarily from:

- PUREVAP™ related sales of $394,444 (Q1, 2023 - $527,600)

- DROSRITE™ related sales of $663,185 (Q1, 2023 - $90,226)

- support services related to systems supplied to the US Navy $1,044,434 (Q1, 2023 - $352,103)

- torch related sales of $877,048 (Q1, 2023 - $1,170,748)

- Refrigerant destruction sales of $102,718 (Q1, 2023 - $67,847)

- biogas upgrading & pollution controls of $32,049 (Q1, 2023 - $32,895)

- other sales and services $372,519 (Q1, 2023 - $350,203)

Q1, 2024 revenues increased by $0.9 million, mainly as a result of:

- PUREVAP™ related sales decreased by $0.1 million due to the completion of the project, with the Company previously announcing the successful silicon “pour” validating all critical milestones and with this achievement, the stage had been set for discussions in transitioning to commercial production,

- DROSRITE™ related sales increased by $0.6 million due to the increase in spare parts orders from existing clients and the increase in storage revenue and other ancillary revenue related to the DROSRITE units, at the request of the client,

- Support services related to systems supplied for the US Navy increased by $0.7 million due to the increase in awarded contracts for spare parts and engineering services from clients that are third-party suppliers of the US Navy,

- Torch-related products and services decreased by $0.3 million, due to the completion of the project, with the Company currently providing continuous 24/7 onsite support.

As of May 14, 2024, revenue expected to be recognized in the future related to backlog of signed and/or awarded contracts is $28.1 million. Revenue will be recognized as the Company satisfies its performance obligations under long-term contracts, which is expected to occur over a maximum period of approximately 3 years.

Cost of Sales and Services and Gross Margins

Cost of sales and services was $2.7 million in Q1 2024, representing an increase of $0.7 million compared with $2.1 million in Q1 2023, primarily due to an increase of $0.2 million in employee compensation, and an increase in direct materials of $0.6 million, due to an increase of on-going projects, offset by the decrease in amortization of intangible assets of $0.1 million compared with $0.2 million for Q1, 2023. This expense variation relates mainly to the intangible assets in connection with the Pyro Green-Gas acquisition, which have been fully amortized by January 2024. These expenses are non-cash items, and the remaining intangible assets are composed of patents and deferred development costs that will be amortized over the expected useful lives.

The gross margin for Q1, 2024 was $0.8 million or 22% of revenue compared to a gross margin of $0.5 million or 20% of revenue for Q1 2023, the increase in gross margin was mainly attributable to the increase in spare parts sales which yield high profit margins by the added benefits from a vast in-house inventory of over 1000 unique items and approximately 40,000 parts, allowing the Company to avoid long lead times on parts, which ultimately, enables the Company to process additional orders in a shorter period of time.

As a result of the type of contracts being executed, the nature of the project activity, as well as the composition of the cost of sales and services, as the mix between labour, materials and subcontracts may be significantly different. In addition, due to the nature of these long-term contracts, the Company has not necessarily passed on to the customer the increased cost of sales which was attributable to inflation, if any. The costs and sales and services are in line with management’s expectations and with the nature of the revenue.

Selling, General and Administrative Expenses

Included within Selling, General and Administrative expenses (“SG&A”) are costs associated with corporate administration, business development, project proposals, operations administration, investor relations and employee training.

SG&A expenses for Q1, 2024 were $4.5 million, representing a decrease of $3.0 million compared to $7.6 million for Q1, 2023. The decrease is a result of a $0.4 million decrease in employee compensation, decreasing to $2.2 million (Q1, 2023 - $2.6 million), share-based expenses decreased by $0.5 million to $0.5 million (Q1, 2023 - $1.0 million), which is a non-cash item and relates mainly to 2022 and 2023 grants not repeated in 2024, professional fees decreased by $0.7 million to $0.6 million (Q1, 2023 - $1.2 million) mainly related to the decrease of $0.4 million of legal fees incurred during the first three-months of 2024. A decrease of other expenses by $0.2 million to $0.7 million (Q1, 2023 - $0.9 million), due to a net reduction of insurance expenses and the expected credit loss & bad debt provision decreased by $1.0 million to $0.4 million compared to $1.4 million recorded in the comparable period. Furthermore, this was offset by the favourable impact of $0.3 million on the foreign exchange charge on materials.

Share-based payment expenses, as explained above, are non-cash expenses and are directly impacted by the vesting structure of the stock option plan whereby options vest between 10% and up to 100% on the grant date and may require an immediate recognition of that cost.

Depreciation on Property and Equipment

The depreciation on property and equipment decreased to $0.1 million in Q1 2024, compared with $0.2 in Q1 2023. The expense is comparable to the same quarter last year and the decrease is primarily due to the nature and useful lives of the property and equipment being depreciated.

Research and Development (“R&D”) Expenses

During the three-months ended March 31, 2024, the Company incurred $0.2 million of R&D costs on internal projects, a decrease of $0.1 million as compared with $0.3 million in Q1 2023. The decrease in Q1 2024 is primarily related to a decrease in other expenses of $0.2 million and offset by the increase in employee compensation of $0.1 million.

In addition to internally funded R&D projects, the Company also incurred R&D expenditures during the execution of client funded projects. These expenses are eligible for Scientific Research and Experimental Development (“SR&ED”) tax credits. SR&ED tax credits on client funded projects are applied against cost of sales and services (see “Cost of Sales” above).

Financial Expenses

Finance expense for Q1 2024 totaled $0.2 million as compared with a finance income of $0.9 million for Q1 2023, representing a variation of $1.1 million year-over-year. The increase in finance expenses in Q1 2024, is mainly due to the increase in interest and accretion related to the convertible debenture and convertible loan issued during 2023. This was offset by the decrease of $1.0 million of the revaluation of the balance due on business combination in Q1 2023 whereby the Company’s Italian subsidiary and a customer both agreed on the final acceptance of a contract, prior to final completion and the Company determined that a milestone related to the business combination would not be achieved. As a result, the contract did not attain the pre-determined milestone in connection with the balance due on business combination, and a reversal of the liabilities was recorded.

Strategic Investments

During the three-months ended March 31, 2024, the adjustment to fair market value of strategic investments for Q1 2024 resulted in a loss of $0.2 million compared to a gain in the amount of $0.3 million in Q1 2023. The decrease in gain is attributable to the variation of the market value of the common shares owned by the Company of HPQ Silicon Inc.

Comprehensive (Loss) Income

The comprehensive loss for Q1 2024 of $4.4 million compared to a loss of $6.2 million, in Q1 2023, represents a variation of $1.8 million, and is primarily attributable to the factors described above, and summarized as follows:

- an increase in product and service-related revenue of $0.9 million arising in Q1 2024,

- an increase in cost of sales and services of $0.7 million, primarily due to an increase in employee compensation, subcontracting, direct materials, manufacturing overhead, and investment tax credits, offset by the decrease in amortization of intangible assets,

- a decrease in SG&A expenses of $3.0 million arising in Q1 2024, was primarily due to a decrease in employee compensation, professional fees, travel, depreciation in property and equipment, other expenses, favourable variation of $0.3 million in foreign exchange charge on materials, and a decrease of $1.0 million of the allowance of credit loss, which is offset by an increase in several non-significant expenses,

- a decrease in share-based expenses of $0.5 million,

- a decrease in R&D expenses of $0.1 million primarily due to a decrease in other expenses, offset by the increase in employee compensation,

- an increase in finance costs (income), net expense of $1.1 million in Q1 2024 primarily due to the revaluation of balance due on business combination,

- a decrease in changes in fair market value of strategic investments of $0.5 million.

Liquidity and Capital Resources

As at March 31, 2024, the Company had cash of $0.2 million, included in the net working capital deficiency of $11.4 million. Certain working capital items such as billings in excess of costs and profits on uncompleted contracts do not represent a direct outflow of cash. The Company expects that with its cash, liquidity position, the proceeds available from the strategic investment and its access to capital markets it will be able to finance its operations for the foreseeable future.

The Company’s term loan balance at March 31, 2024 was $350,822 and decreased by $53,257 since December 31, 2023, due to the complete reimbursement of a loan. The decrease from January 1, 2023, to December was mainly attributable to the accretion on the Economic Development Agency of Canada loan, which is interest free and will remain so, until the balance is paid over the 60-month period ending March 2029. In July 2023, the Company closed a brokered private placement for $3,030,000, bearing interest at 10%. On December 20, 2023, the Company closed a non-brokered private placement of a convertible loan for gross proceeds of $1,250,000 and bears interest at 3%. The average interest expense on the other term loans and convertible debenture is approximately 10%. The Company does not expect changes to the structure of term loans and convertible debentures and loans in the next twelve-month period. The Company maintained one credit facility which bears interest at a variable rate of prime plus 1%, therefore 8.20% at March 31, 2024. The Company will continue to reimburse the existing credit facility in 2024.

OUTLOOK

Consistent with the Company’s past practice, and in view of the early stage of market adoption of our core lines of business, the Company is not providing specific revenue or net income (loss) guidance for 2024.

The following is an outline of the Company’s strategy plus key developments that are expected to impact subsequent quarters.

Overall Strategy

PyroGenesis provides technology solutions to heavy industry that leverage the Company’s expertise in ultra-high temperature processes. The Company has evolved from its early beginnings as a specialty-engineering firm to being a provider of a robust technology eco-system for heavy industry that helps address key strategic goals.

The Company believes its strategy to be timely, as multiple heavy industries are committing to major carbon and waste reduction programs at the same time as many governments are increasingly supportive – from both a policy and financial perspective – of environmental technologies and infrastructure projects. Additionally, both industry and government are developing strategies to ensure the availability of critical minerals during the coming decades of increased output demand.

While there can be no guarantees, the Company believes the evolution of its strategy beyond greenhouse gas emission reduction, to an expanded focus that encapsulates the key verticals listed in the section “Q4 Production and Sales Highlights”, both (i) improves the Company’s chances for success while (ii) also providing a clearer picture of how the Company’s wide array of offerings work in tandem to support heavy industry goals.

PyroGenesis’ market opportunity is significant, as major industries such as aluminum, steelmaking, manufacturing, cement, chemicals, defense, aeronautics, and government seek factory-ready, technology-based solutions to help steer through the paradoxical landscape of increasing demand, tightening regulations, and material availability.

As more of the Company’s offerings reach full commercialization, PyroGenesis will remain focused on attracting influential customers in broad markets while at the same time ensuring that operating expenses are controlled to achieve profitable growth.

Cost Controls and Efficiencies

PyroGenesis has, and continues to, scrutinize both potential and existing projects to ensure that the utilization of labour and financial resources are optimized. The Company continues to only engage in projects that reflect significant benefits to PyroGenesis and the risks of which are defined. The Company intends to intensify its focus on project and budgetary clarity during this period of elevated inflationary pressures, by identifying alternative suppliers while constantly adjusting project resources. The early-stage project assessment process has also been refined to allow for a faster “go / no-go” decision on project viability.

Enhanced Sales and Marketing

Against the backdrop of this 3-tiered strategy, the Company continues to increase sales, marketing, and R&D efforts in-line with – and in some cases ahead of – the growth curve for industrial change related to greenhouse gas reduction efforts.

Macroeconomic Conditions

With some continued uncertainty in the macroeconomic environment, including ambiguity in the banking sector with regard to interest rate adjustments, and the continued inflationary pressures causing shifting demand dynamics across various industries at different times, it may be difficult to assess the future impact these events and conditions will have on our customer base, the end markets we serve and the resulting effect on our business and operations, both in the short term and in the long term.

Despite these uncertainties, we continue to believe there is an accelerated need for PyroGenesis’ solutions in the industries we serve as heavy industry continues to decarbonize / transition their energy sources, manufacture utilizing both lighter metals (such as aluminum) and additive manufacturing, and tighten hazardous waste regulations.

We expect these uncertainties, or other macroeconomic conditions, to continue to cause variability in our quarter to quarter revenue. However, we believe our diversity in both customer base and solution set will continue to be a strong mitigating factor to these challenges.

The various military conflicts in the middle east and Eastern Europe continue to create some level of global economic uncertainty, as well as supply chain disruptions that can change at any time. However, it’s important to note that the Company does not have any operations, customers or supplier relationships in Russia, Belarus or Ukraine, and as such are not directly impacted at a customer level in these countries. The Company does have customer relationships and projects in Poland and will continue to monitor the situation in the region regarding challenges to the completion of current projects, which at this time are not inhibited.

As always, the Company monitors the potential impact macroeconomic events and conditions could have on the business, operations, and financial health of the Company.

Generally, the Company believes that broad-based threats to global supply chains increase awareness and interest in the many solutions the Company offers. This is particularly true within the minerals and metals industries, as manufacturers seek alternatives to off-shore suppliers as well as technologies that could optimize output or recycle critical material from byproducts or waste – solutions that the Company currently offers.

Business Line Developments

The upcoming milestones which are expected to confirm the validity of our strategies are outlined below (please note that these timelines are estimates based on information provided to us by the clients/potential clients, and while we do our best to be accurate, timelines can and will shift, due to protracted negotiations, client technical and resource challenges, or other unexpected situations beyond our or the clients’ control):

Business Line Developments: Near Term (0 – 3 months)

Energy Transition & Emission Reduction

Aluminum Remelting Furnaces:

As mentioned in the 2023 Q2 Outlook, the Company has been working on aluminum remelting furnace solutions using plasma, for use by secondary aluminum producers or any manufacturer of aluminum components that uses recycled or scrap aluminum.

With gas-fired furnaces responsible for much of the scope 1 emissions of secondary aluminum production, aluminum companies have been searching for solutions that can help in the decarbonization efforts of aluminum remelting and cast houses.

The Company has two concepts: the retro-fitting of plasma torches in existing remelting and cast house furnaces that currently use other forms of heating, such as natural gas; and the manufacturing and sale of a PyroGenesis produced furnace based off the Company’s existing Drosrite metal recovery furnace design, which has been in use commercially for several years.

Also as mentioned in the Q2 and Q3 Outlooks, the Company has been working with different companies over the past few years towards these goals. The results from the conclusion of recent major tests, conducted in conjunction with one of these companies, have been very positive. Negotiations are underway with that client for next step deployments and/or sales and, if additional contracts are concluded, more detailed announcements on these projects may be expected during Q2 2024.

Post quarter end, in April 2024 [news release dated April 10, 2024], the Company announced the signing of a letter of intent for large-scale plasma remelting furnaces, with Constellium, one of the world’s largest aluminum transformation and recycling companies. The project consists of two phases: i) conducting feasibility studies and engineering; and ii) implementing a demonstrator plasma-heated furnace system in one of Constellium’s aluminum casthouses.

Aluminum Furnace Tests:

The Company is in advanced discussions with major aluminum companies for live furnace tests of plasma as a process heat source in melting and holding furnaces.

Steel Industry Energy Transition:

Post quarter end, in April 2024 [news release dated April 24, 2024], the Company announced the signing of a contract with one of the five largest steelmakers globally, to assess the applicability of PyroGenesis’ fully electric plasma torches for use in the client’s manufacturing facilities as a primary heat source in the steelmaking process, specifically during the production of direct reduced iron (DRI) for use in electric arc furnaces (EAF). The first step is a feasibility study to gather initial data for evaluating the potential use of plasma in the client’s factories as a process heating source for the DRI process. The duration of the study is approximately 60 days, commencing in April 2024.

Once the study is completed, and contingent on the results, the client has indicated that it may proceed to a live experimental validation study within their facilities, using PyroGenesis’ plasma torches, as per a separate to-be-negotiated agreement.

New Industry Contract for Plasma Torches:

As noted in the Q1 Production and Sales Highlights above, in January 2024, the Company announced the signing of a framework master agreement with a client (whose name is being withheld for confidentiality and competitive reasons), which included the payment to the Company of a non-refundable downpayment for $667,000. As stated in the Q4 2023 Outlook, this marks PyroGenesis’ resumption of work in an industry that previously showed promise.

Negotiations of a first substantial statement of work are ongoing and remain positive but depend in large part on the client’s ability to secure funding in a timely manner. The client now anticipates proceeding with the purchase of a single plasma torch system in the near term, followed by one or more larger orders in subsequent quarters, dependent upon financing. While there is no guarantee this statement of work or additional ones will be completed, if successful the Company foresees the potential for a multi-phase, multi-year partnership with the client that may result in many additional plasma torch orders over the next few years.

Iron Ore Pelletization Torch Trials:

As mentioned in previous Outlooks, the commissioning of the plasma torch systems – for use in the pelletization furnaces of a client previously identified as Client B – was underway, with the Company’s engineers onsite at Client B’s iron ore facility. The commissioning process includes installation, start-up, and site acceptance testing (SAT). The Company previously announced that it had shipped four 1 MW plasma torch systems for use in Client B’s iron ore pelletization furnaces, for trials toward potentially replacing fossil-fuel burners with plasma torches in Client B’s furnaces.

As mentioned in previous Outlooks, this project continues to move forward, however the commissioning suffered a series of unforeseeable delays caused by, among other things, damaging regional torrential rainstorms that flooded and damaged the facility’s electrical system and furnace components, and intermittent power outages that led to damage of the plasma burners cooling system.

Client B remains committed to the trials and additional process steps are being designed and engineered to account for the client’s particular mechanical and environmental risk variables.

The client previously identified as Client A, a large international mining company which has also purchased a full plasma torch system for use in trials in its pelletization furnaces, continues its plasma torch initiative at its own pace, with no recent developments to report as per project timing or completion.

Pyro Green-Gas:

The Company’s wholly owned subsidiary, Pyro Green-Gas, is in advanced discussions with an international steel company for a project with a value of approximately $1.1 million, which it expects to resolve in the near term.

Aluminum Cast House Decarbonization:

The Company is part of a tendered bid process for the testing of plasma within an aluminum cast house of a leading global aluminum company. This is unrelated to the project announcement made in conjunction with Constellium.

Mining Industry Parts Manufacturer Decarbonization:

Post quarter end, in April 2024 [news release dated April 17, 2024], the Company announced the signing of a contract with a client to assess the applicability and examine the use of plasma as a heat source in the client’s cast furnaces. The client, a billion-dollar entity with facilities on five continents, is one of the world’s largest manufacturers of products that serve the mining and defense industries, amongst others.

The tests contemplated by this initial engagement should be completed by the end of the second quarter. Should the tests prove successful, it is expected that the client will move to step 2, which envisions producing a complete plasma torch-based system for use on-site to replace an existing fossil fuel burner. Such a system would include a PyroGenesis plasma torch as well as the accompanying manipulation/handling components. Step 2 would take approximately 6 months depending on the delivery time of a specific long lead item (the power supply) and generate approximately US$500,000-$1,000,000 in revenues to PyroGenesis.

Commodity Security & Optimization

New Laser Cut Titanium Metal Powder Order:

Post quarter end, in April 2024 [news release dated April 30, 2024], the Company announced the signing of an initial contract with an aerospace entity in Spain for the sale of PyroGenesis’ titanium metal powder for use in additive manufacturing. The client is engaged in the development of advanced aeronautics technologies for the European aerospace industry. This new order is for titanium metal powder with a particle size range of 15-63µm. This powder cut range is ideally suited for laser bed additive manufacturing methods, including Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM), which are widely recognized for their precision and strength in creating complex metal compounds.

The order has already been produced using PyroGenesis’ NexGen™ plasma atomization system, and is expected to be delivered to the client in the near term.

This contract represents the Company’s initial commercial metal powder order direct from a European client, a significant milestone under the Company’s new direct distribution strategy.

Additive for Green Cement:

The Company had previously announced a project with client Progressive Planet, for the development of amorphous silica from crystalline silica, for use as an additive to replace fly ash in cement, thereby creating green cement.

Post quarter end, in May 2024 [news release dated May 2, 2024], the Company announced the results of a 28-day lab strength tests, which achieved up to 99.56% above compressive strength target for cement additive products.

Product Qualification Process for Global Aerospace Firm:

As mentioned in the Q3 Outlook, based on information flow between the Company and the aerospace client previously announced, the Company believes that the 3-year long qualification process to approve the Company’s titanium metal powers for use by a global aerospace firm and their suppliers, will conclude in the near term.

Of note, the Company previously confirmed that the qualification process includes both PyroGenesis’ “coarse cut” titanium metal powder, in addition to the “fine cut” titanium metal powder that had been previously discussed as undergoing the qualification process.

The Company has some expectations that the course cut may receive qualification first, which would be advantageous to the Company, as the course cut has been produced and stockpiled in large amounts at the PyroGenesis facility, so delivery readiness would be enhanced.

“FSR” Project:

Fumed Silica (also known as Pyrogenic Silica) is a particle-size food-safe additive with a large surface area, used worldwide as a thickening agent in thousands of products such as milkshakes, adhesives, powdered foods, paints, inks, cosmetics, and beverages, to increase strength, viscosity, and flow control.

PyroGenesis developed the Fumed Silica Reactor (“FSR”), a plasma-based process that creates fumed silica from quartz in a single and eco-friendly step, and sold the FSR technology to HPQ Silica Polvere Inc., a subsidiary of HPQ Silicon Inc. as part of a development agreement. By eliminating the use of harmful chemicals generated by conventional fumed silica production methods, the groundbreaking FSR approach, if successful, will help contribute to the repatriation of silica production to North America while lowering the CO2 emissions and carbon footprint of the process. In a major step towards commercial-scale production, PyroGenesis successfully deployed [news release dated Oct 3, 2023] the FSR on a laboratory scale to produce fumed silica. A subsequent independent analysis [news release dated Nov 9, 2023] of the material conducted by McGill University confirmed the commercial-quality and thickening efficiency of the fumed silica produced by the FSR.

The build of a pilot plant for HPQ Silica Polvere Inc. has commenced for pre-commercial sample batch production of fumed silica, for launch in Q2 2024. In addition to being the engineering services provider and developer of the forthcoming pilot plant, PyroGenesis owns a 10% royalty of client HPQ’s eventual fumed silica sales, with set minimums. This royalty stream can, at any time, be converted by PyroGenesis into a 50% ownership of HPQ’s ownership stake in HPQ Silica Polvere Inc.

Metal Extraction and Recovery Project:

The Company is in advanced discussions with a US-based entity who desires to utilize the Company’s plasma technology to extract valuable minerals and metal from different sources of ore. The Company has ownership of thousands of tonnes of ore. Designed as a potential three-phase project, the project values range from $50,000 for phase one (near term) to up to $5 million+ in phase three (mid term).

Waste Remediation

SPARC Refrigerant Waste Destruction System:

The Company had previously announced that it was in the final phase of a tendered bid process for the safe destruction of hazardous end-of-life refrigerants, such as CFCs, HCFCs, and HFCs, for a contract amount of approximately $6.5 million. The Company’s Steam Plasma Refrigerant Cracking (SPARC) system was named as a finalist for this Asian client’s initiative. The potential client subsequently decided not to destroy the waste in a non-combustible, emission-free manner, choosing instead to utilize an existing incineration facility to collect and potentially incinerate the refrigerants, as regulations in that jurisdiction allow. The Company remains in contact with the potential client and will re-commit to negotiations if the potential client decides to reassess their approach at a later date.

Financial

Payments for Outstanding Major Receivables:

The Company has remained in continuous discussions with Radian Oil and Gas Services Company regarding the outstanding receivable of approximately US$8.0 million under the Company’s existing $25 million+ Drosrite™ contract. As previously announced, PyroGenesis agreed to a strategic extension of the payment plan, by the customer and its end-customer, geared to better align the pressures on the end-user’s operating cash flows created by increased business opportunities.

These discussions have been positive, both in regard to the ongoing payment plan, and in regard to a potential new order of additional Drosrite™ systems, as the client’s cash flow situation and business opportunities continue to improve.

As noted in the 2023 year-end Outlook, the Company now expects payment of the balance of this receivable to commence in Q2 2024.

Innovation Grants:

As mentioned in the Q1 and Q2 Outlooks, the Company has applied for grants tailored to technology innovation and/or carbon reduction and expects to have results regarding these applications. Indications are positive and the Company expects to be in a position to make an announcement on these grants in Q2 2024. These grants are in the order of $1-2 million.

Business Line Developments: Mid Term (3 – 6 months)

Commodity Security & Optimization

Drosrite Factory Trials:

The Company is in discussions with multiple aluminum manufacturers to conduct paid tests of its Drosrite aluminum dross processing systems within client factories, as a first step towards potential purchase of Drosrite systems. These particular potential clients are located across Europe and the United States.

Drosrite Systems:

Separately, the Company is in various stage discussions with multiple aluminum manufacturers to purchase Drosrite aluminum dross processing systems.

Waste Remediation

Plasma Resource Recovery System (PRRS):

The Company is in early-stage discussions for the sale of a PRRS system, to a European entity, to transform municipal solid waste (MSW) into both energy and chemical products. PyroGenesis’ PRRS system is designed to process MSW, industrial waste, and hazardous waste, transforming such into commercially valuable products. These products include gaseous fuel for electricity and heat generation, slag, aggregates suitable for construction, and recoverable metals for recycling. The potential value for this contract is approximately $25 - $30 million.

Potential PAWDS Order:

The Company is in initial negotiations with a company that conducts cleanup and destruction of waste from seawater. It has also indicated interest in carrying out similar initiatives on land in remote locations. Negotiations for a PyroGenesis Plasma Arc Waste Destruction System (PAWDS), similar to the type the Company designed and built for some of the U.S. Navy aircraft carriers, are in early stage. While there is no guarantee this contract is completed, if successful the Company would be contracted for multiple PAWDS systems.

** Please note that projects or potential projects previously announced that do not appear in the above summary updates should not be considered as at risk. Noteworthy developments can occur at any time based on project stages, and the information presented above reflects information on hand. Projects not mentioned may have simply not concluded or not passed milestones worthy of discussion.

About PyroGenesis Canada Inc.

PyroGenesis Canada Inc., a high-tech company, is a proud leader in the design, development, manufacture and commercialization of advanced plasma processes and sustainable solutions which reduce greenhouse gases (GHG) and are economically attractive alternatives to conventional “dirty” processes. PyroGenesis has created proprietary, patented and advanced plasma technologies that are being vetted and adopted by multiple multibillion dollar industry leaders in four massive markets: iron ore pelletization, aluminum, waste management, and additive manufacturing. With a team of experienced engineers, scientists and technicians working out of its Montreal office, and its 3,800 m2 and 2,940 m2 manufacturing facilities, PyroGenesis maintains its competitive advantage by remaining at the forefront of technology development and commercialization. The operations are ISO 9001:2015 and AS9100D certified, having been ISO certified since 1997. For more information, please visit: www.pyrogenesis.com.

Cautionary and Forward-Looking Statements

This press release contains “forward-looking information” and “forward-looking statements” (collectively, “forward-looking statements”) within the meaning of applicable securities laws. In some cases, but not necessarily in all cases, forward-looking statements can be identified by the use of forward-looking terminology such as “plans”, “targets”, “expects” or “does not expect”, “is expected”, “an opportunity exists”, “is positioned”, “estimates”, “intends”, “assumes”, “anticipates” or “does not anticipate” or “believes”, or variations of such words and phrases or state that certain actions, events or results “may”, “could”, “would”, “might”, “will” or “will be taken”, “occur” or “be achieved”. In addition, any statements that refer to expectations, projections or other characterizations of future events or circumstances contain forward-looking statements. Forward-looking statements are not historical facts, nor guarantees or assurances of future performance but instead represent management’s current beliefs, expectations, estimates and projections regarding future events and operating performance.

Forward-looking statements are necessarily based on a number of opinions, assumptions and estimates that, while considered reasonable by the Company as of the date of this release, are subject to inherent uncertainties, risks and changes in circumstances that may differ materially from those contemplated by the forward-looking statements. Important factors that could cause actual results to differ, possibly materially, from those indicated by the forward-looking statements include, but are not limited to, the risk factors identified under “Risk Factors” in the Company’s latest annual information form, and in other periodic filings that the Company has made and may make in the future with the securities commissions or similar regulatory authorities, all of which are available under the Company’s profile on SEDAR+ at www.sedarplus.ca. These factors are not intended to represent a complete list of the factors that could affect the Company. However, such risk factors should be considered carefully. There can be no assurance that such estimates and assumptions will prove to be correct. You should not place undue reliance on forward-looking statements, which speak only as of the date of this release. The Company undertakes no obligation to publicly update or revise any forward-looking statement, except as required by applicable securities laws.

Neither the Toronto Stock Exchange, its Regulation Services Provider (as that term is defined in the policies of the Toronto Stock Exchange) nor the OTCQX Best Market accepts responsibility for the adequacy or accuracy of this press release.

For further information please contact:

Rodayna Kafal, Vice President, IR/Comms. and Strategic BD

E-mail: ir@pyrogenesis.com

RELATED LINK: http://www.pyrogenesis.com/

A photo accompanying this announcement is available at: https://www.pyrogenesis.com/wp-content/uploads/2023/08/Solution-Ecosystem2.png