Advanced Industrial, a leader in high-performance polymer solutions, is setting a new standard in manufacturing with its advanced PEEK plastic material. Known for its exceptional strength, chemical resistance, and thermal stability, PEEK plastic has become a critical component in industries demanding precision and durability. With decades of expertise in polymer distribution and CNC machining, Advanced Industrial is leveraging its capabilities to support sectors such as aerospace, medical, energy, and industrial manufacturing.

As manufacturers continue to seek materials that offer both performance and reliability, Advanced Industrial’s PEEK plastic material is proving to be a game-changer. The company’s deep understanding of high-performance polymers allows it to supply PEEK solutions that meet the most demanding operational requirements. With applications ranging from high-stress mechanical components to medical implants and lightweight aerospace parts, PEEK plastic delivers the strength of metal while maintaining the advantages of a lightweight, corrosion-resistant polymer.

“PEEK plastic is one of the most versatile and reliable materials available for extreme environments,” said Paul Cedrone, CEO of Advanced Industrial. “Our team is committed to pushing the boundaries of what’s possible with this advanced polymer, ensuring our customers receive solutions that optimize performance, longevity, and efficiency.”

As a trusted distributor of PEEK plastic material, Advanced Industrial ensures that manufacturers have access to high-quality stock shapes, including rods, sheets, and tubes, as well as precision-machined components. With its advanced CNC lathes and CNC mills, the company is also capable of machining PEEK to tight tolerances, allowing customers to receive finished parts that meet exact specifications. Whether a client needs raw PEEK material for in-house machining or fully machined components for immediate use, Advanced Industrial delivers high-performance solutions backed by extensive industry expertise.

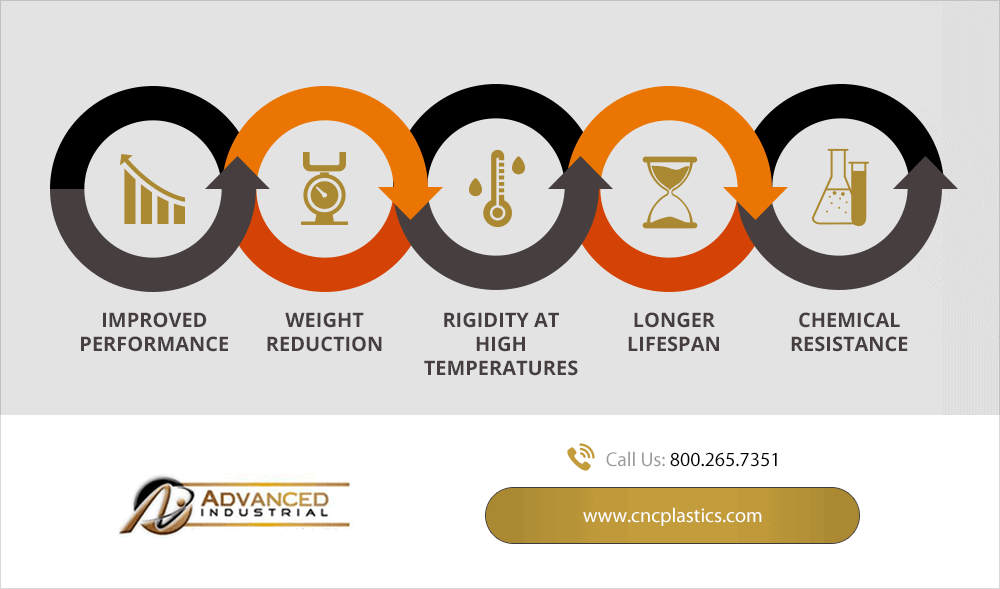

PEEK plastic material from Advanced Industrial offers a unique combination of properties that make it highly sought after in various industries. Its resistance to wear, fatigue, and chemicals makes it an ideal choice for high-stress applications, while its lightweight nature helps reduce overall system weight in transportation and aerospace applications. Additionally, its ability to maintain mechanical integrity at high temperatures further sets it apart from conventional materials.

One of the key advantages of working with Advanced Industrial is its ability to provide technical expertise and support in material selection. With a deep understanding of PEEK’s mechanical and thermal properties, the company helps customers determine the best grades and configurations for their specific applications. Whether a project requires unfilled PEEK for general-purpose use or carbon-filled PEEK for enhanced strength and wear resistance, Advanced Industrial ensures that clients receive the right materials for their needs.

“Our customers rely on us to provide materials that meet their most challenging specifications,” Cedrone added. “PEEK plastic is an incredible solution for applications where failure is not an option, and we take pride in delivering products that stand up to the toughest conditions.”

Industries such as oil and gas, semiconductor manufacturing, and medical device production have increasingly turned to Advanced Industrial’s PEEK plastic material for its superior performance. In the medical field, its biocompatibility and sterilization resistance make it a preferred choice for implants and surgical instruments. In the semiconductor industry, its low outgassing and chemical resistance properties make it essential for high-purity processing environments.

With the growing demand for high-performance materials, Advanced Industrial continues to invest in research and development to further expand the capabilities of PEEK plastic. The company is constantly exploring new ways to improve processing techniques, expand its inventory, and develop partnerships that strengthen its position as a leading supplier in the industry.

As industries continue to push the limits of material performance, Advanced Industrial remains at the forefront of innovation, delivering solutions that combine engineering excellence with real-world reliability. By staying ahead of industry trends and leveraging decades of expertise, the company is well-positioned to meet the increasing demand for PEEK plastic components across a range of applications.

“Every project we take on is an opportunity to help our customers achieve greater efficiency, durability, and performance,” Cedrone said. “PEEK plastic is a material that truly stands out in the world of engineering polymers, and we’re proud to be a trusted partner for companies that need the best in polymer solutions.”

With a commitment to quality, precision, and innovation, Advanced Industrial continues to lead the way in high-performance PEEK plastic solutions. As industries evolve and new challenges emerge, the company remains dedicated to providing advanced materials that help manufacturers achieve their goals while meeting the highest standards of performance and reliability.

###

For more information about Advanced Indsutrial, contact the company here:

Advanced Indsutrial

Paul Cedrone

800-865-7351

info@cncplastics.com

112 Meadow Hill Circle

Mooresville, NC 28117